FieldVent by Northrop Grumman

Northrop Grumman’s FieldVent was designed for rapid mass production using a non-medical supply chain. Central to the design was ease of assembly, compact yet socially distanced production lines, and simple test procedures to make it inherently affordable. To further support mass producibility, components and parts available in volumes of 10,000 per week with short lead times were used. In mid-April 2020, with support of Dr. Nader M. Habashi, renowned critical care intensivist and pulmonologist from the University of Maryland Medical Center and affiliated R Adams Cowley Shock Trauma Center, it passed extensive government testing and is currently estimated to cost less than $1,000 per unit to build with a wide variety of nontraditional manufacturers able to produce it.

“The people on the team like solving problems, but we all felt that it was an important thing to work on,” said FieldVent team member Jay Switzer. “If we could put some ideas out there and have them be of merit, it’s for the greater good. There’s nothing more important than that.”

Northrop Grumman is working to get the design through FDA Emergency Use Authorization (EUA) and is providing the DoD full and unlimited rights to the intellectual property. Thanks to Northrop Grumman’s spirit of innovation, the DoD will have the design at their disposal should it be needed to save lives during the pandemic.

Characteristics

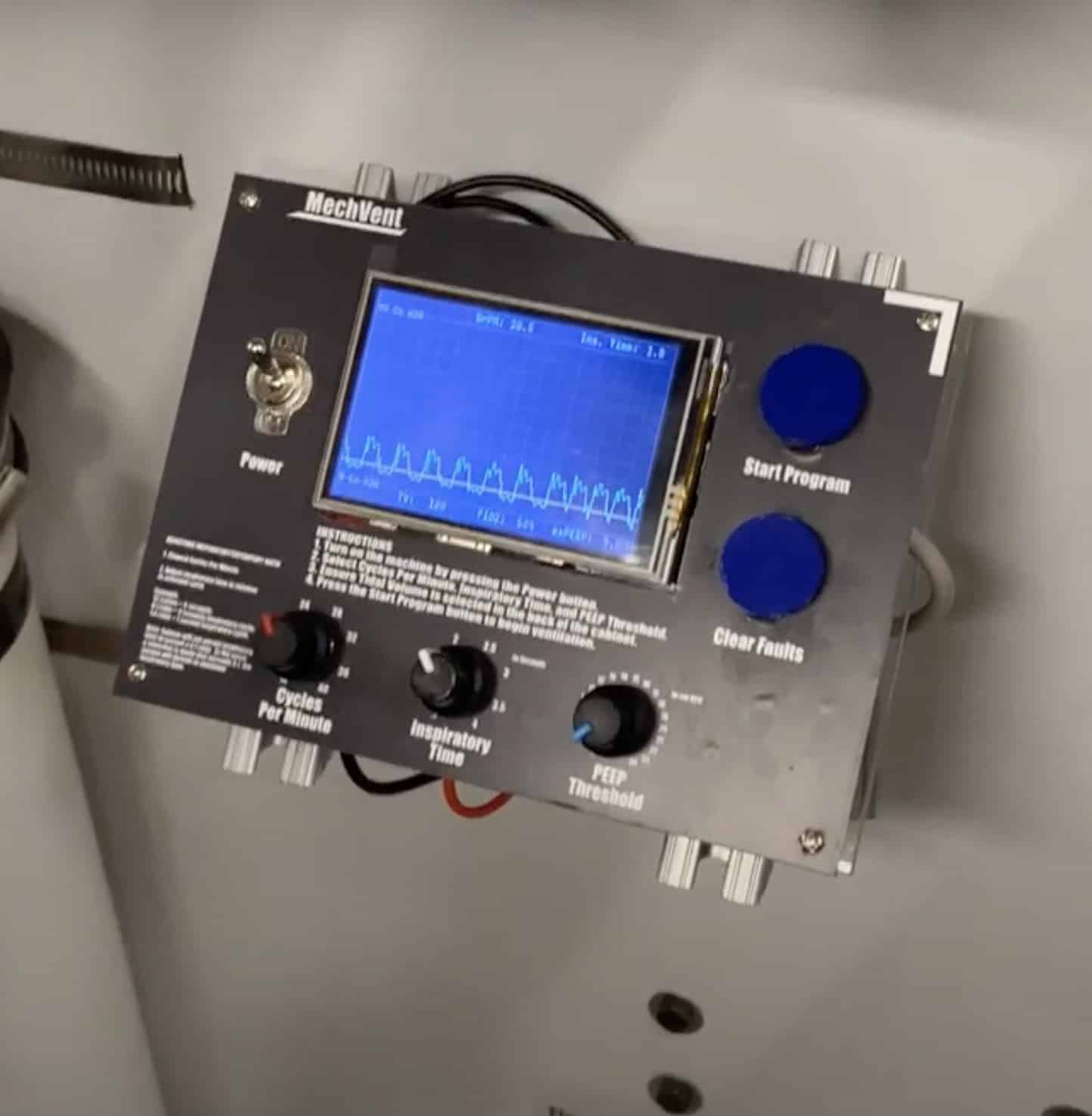

- No soft settings; all hard settings for simplicity and robustness

- Uses HEPA bacteria/viral filter

- On-screen monitoring and audible alarms

- Goal is extremely low cost and easy to manufacture in mass as a contingency ventilator

Specifications

| RR (Hz) | 12-40 |

| TV (mL) | 250-800cc |

| Flow Rate (L/min) | 3-32 L/m |

| PIP (cm H20) | 18-40 |

| PEEP (cm H20) | 4-25 |

| Available Ventilation Modes | Volume control |

| Air Source | Piston Pump using entrained air |